Hydrogen peroxide catalyst

Hydrogen peroxide catalystHydrogen peroxide is a kind of green chemical products, its production and use process almost no pollution, it is called "clean" chemical products, application prospects are very good. Initially, hydrogen peroxide was only used in the pharmaceutical and military industries. Later, it was gradually applied in chemical synthesis, textile, paper making, environmental protection, food and agriculture, and the market demand was expanding day by day.

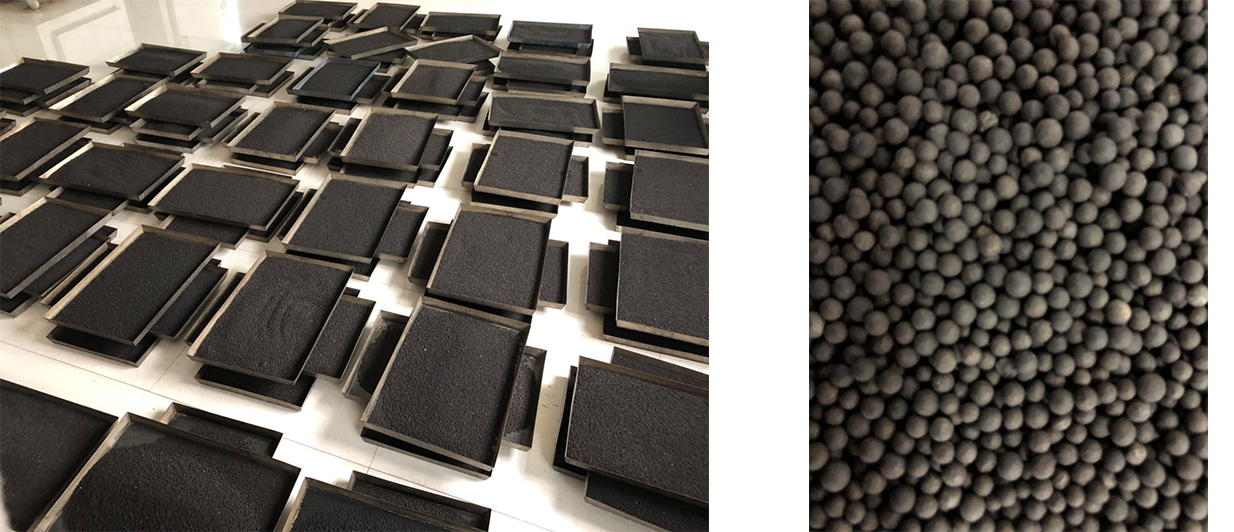

In 2000, shaanxi kaida started to study on palladium catalyst and its preparation method for producing hydrogen peroxide by anthraquinone method, which solved the problems and technical defects in the technology, including the balance of catalyst activity and sample selection, low strength of catalyst carrier, easy pulverization and crushing, service life and regeneration period of catalyst, etc. The final preparation of palladium catalyst for the production of anthraquinone hydrogen peroxide has a very balanced surface area, pore volume and pore diameter distribution match, and ensures that the overall particle compressive strength of the catalyst is greatly improved, the abrasion value is greatly reduced, the catalyst is not easy to powder, broken, greatly extend the service life and regeneration cycle.

Active alumina is used as catalyst carrier in kaida, shaanxi province. The spherical alumina is formed by adding pore expanding agent asymmetrically. The surface longitudinal distribution of the spherical alumina carrier is asymmetrically distributed along the radial direction of the carrier. It not only ensures the large surface hole and low specific surface area of the catalyst carrier, but also achieves the characteristics of high compressive strength of the catalyst as a whole. The main active component of the catalyst is all-metal palladium. In the process of maintaining the catalysis, the impregnation effect of the active component can be achieved with controllable depth by adjusting the type and amount of the active component positioner before the carrier is sprayed.

In the process of research and development, the company has optimized the preparation of carrier, the impregnation depth of active components and the control of metal dispersion, so that the pore size nonlinear distribution catalyst prepared by the company shows good activity and selectivity in industrial applications, and overcomes various defects of existing technologies.

Shaanxi kaida research and development of hydrogen peroxide catalyst, to solve the technical problems and technical defects, including catalyst activity, the balance of sample selection, catalyst carrier strength is low, easy to powder and broken, catalyst service life and regeneration cycle and other issues. The final preparation of palladium catalyst for the production of anthraquinone hydrogen peroxide has a very balanced surface area, pore volume and pore diameter distribution match, and ensures that the overall particle compressive strength of the catalyst is greatly improved, the abrasion value is greatly reduced, the catalyst is not easy to powder, broken, greatly extend the service life and regeneration cycle; Activated alumina is used as catalyst carrier and the spherical alumina is formed by adding pore expanding agent asymmetrically. The surface longitudinal distribution of the spherical alumina carrier is asymmetrically distributed along the radial direction of the carrier. It not only ensures the large surface hole and low specific surface area of the catalyst carrier, but also achieves the characteristics of high compressive strength of the catalyst as a whole. The main active component of the catalyst is all-metal palladium. In the process of maintaining the catalysis, the impregnation effect of the active component can be achieved with controllable depth by adjusting the type and amount of the active component positioner before the carrier is sprayed.

II. Product features

Shaanxi kaida research and development of hydrogen peroxide catalyst, to solve the technical problems and technical defects, including catalyst activity, the balance of sample selection, catalyst carrier strength is low, easy to powder and broken, catalyst service life and regeneration cycle and other issues. The final preparation of palladium catalyst for the production of anthraquinone hydrogen peroxide has a very balanced surface area, pore volume and pore diameter distribution match, and ensures that the overall particle compressive strength of the catalyst is greatly improved, the abrasion value is greatly reduced, the catalyst is not easy to powder, broken, greatly extend the service life and regeneration cycle; Activated alumina is used as catalyst carrier and the spherical alumina is formed by adding pore expanding agent asymmetrically. The surface longitudinal distribution of the spherical alumina carrier is asymmetrically distributed along the radial direction of the carrier. It not only ensures the large surface hole and low specific surface area of the catalyst carrier, but also achieves the characteristics of high compressive strength of the catalyst as a whole. The main active component of the catalyst is all-metal palladium. In the process of maintaining the catalysis, the impregnation effect of the active component can be achieved with controllable depth by adjusting the type and amount of the active component positioner before the carrier is sprayed.

III. Industrial use report

Since 2000, shaanxi kaida has entered the palladium catalyst field for hydrogen peroxide. It is responsible for improving the surface properties of the catalyst used for producing hydrogen peroxide by anthraquinone method, improving the performance of the carrier and the preparation process of the catalyst, adding active ingredients, reducing the load of palladium and improving the service life of the catalyst.

In 2012, the 40 ton catalyst KD_PH_PD_02 was successfully tested. The catalyst was loaded in a company's hydrogen peroxide workshop in February 2012. The kettle number was B and C, and each kettle was filled with 20 tons of catalyst. Through reagent production and operation, the production capacity of the catalyst exceeded 5.0kgH2O2 100%/kg cat.d, and the average daily output of hydrogen peroxide reached 325 tons H2O2 27.5%/ day, greatly exceeding the full load design index of 300 tons H2O2 27.5%/ day.

However, the catalytic activity of similar domestic catalysts is generally about 3.3-3.6kg H2O2 100%/kg cat.d. Catalyst as A mainstream domestic supply SC - AO3 under the same reaction conditions, into the bed temperature of 56 degrees Celsius, need to be used A/B two series catalyst, production capacity of 3.6 kg of 100% H2O2 / kg the d, A company hydrogen peroxide alumina catalyst for industrial use results show that the pore size distribution of nonlinear high alumina palladium catalyst hydrogenation activity and selectivity enhanced obviously, the system of effective anthraquinone stability. Therefore, it is concluded in the application report that under the same reaction condition, KD_PH_PD_02 of our company is better than sc-ao3 catalyst of Shanghai, and is completely suitable for the device.

陕公网安备 61030502000254号

陕公网安备 61030502000254号